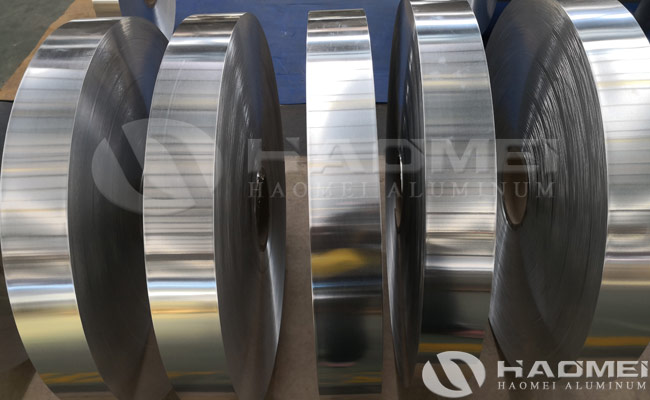

Quality checklist of aluminium strips for sale

The raw material of the aluminium strips for sale is pure aluminum or aluminum alloy cast-rolled aluminum coil, hot-rolled aluminum coil. Which is rolled into a thin-plate aluminum coil of different thickness and width by a cold rolling machine, and then longitudinally slit by a slitting machine to aluminum strips with different widths according to the use.

In the process of rolling the strip blank into various semi-finished and finished aluminum strips, and in the production process of foil finishing, annealing, transfer, packaging and other processes, some defects will inevitably occur. Part of the occurrence of these aluminum strip quality defects is the defects of the ingot and the casting and rolling strip itself. Sometimes it can be exposed in the process of ingot injection and casting and rolling, and sometimes it cannot be found, and it can only be exposed during the subsequent further processing. The other quality defects are produced during the production process of rolling, finishing, annealing, transshipment, packaging and other processes.

Most of these defects are caused by equipment failures, violations of operating procedures, improper adjustment of process parameters, inadequate skill of operators, and various other reasons. In the production process of aluminum strips for sale, there are many kinds of quality defects of aluminum strips, mainly a large number of pinholes, excessive thickness, poor flatness, and broken tapes of various reasons. Reducing these defects is important and very meaningful for improving the quality of aluminum strip foil.

Related News

- Aluminium Foil For Transformer Usage

- 3004 Aluminum Strip For Lamp Cap

- Aluminum Strips For Medical Bottle Cap

- Aluminum Strip For Louver

- Dry Transformer Aluminum Strip

- Aluminum Strip for Ductwork

- Aluminium strips for cookie cutters

- Coiled Aluminum Strip

- Aluminium Strip For Electrical Transformer Winding

- Aluminium strip belt for duct