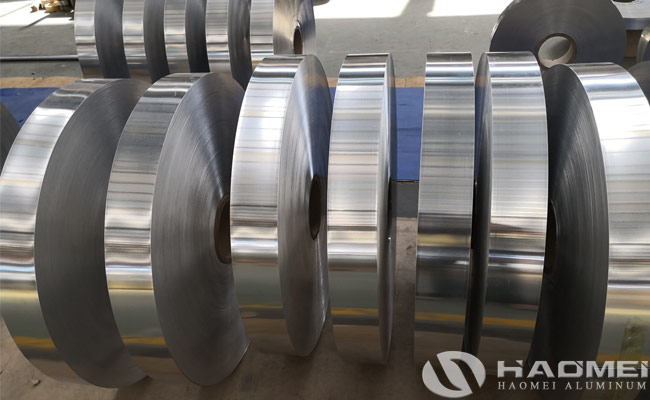

Flat aluminum strips quality requirements

Flat aluminum strips are widely used in industrial area, so they have strict quality requirements on the specification, surface, edge and performance. The thickness should be uniform, the width should be uniform, no color difference, no wrinkles, discounts, no cracks, burrs, at the edges. The end face is neat and free of channeling.

The common terms for flat aluminium strips are:

Diagonal: the diagonal tolerance of aluminum strips. Generally speaking, the diagonal tolerance of flat aluminium strip cannot be greater than 2 mm, otherwise it will deform.

Thickness tolerance: During the production process, there will be a certain gap in the thickness of flat aluminum strips. According to the requirements, the thickness tolerance of aluminum strips is usually within 0.8-1.0 mm (determined according to the thickness of aluminum strips).

Length and width tolerance: The gap between the length and width of aluminum strip during the production process is usually implemented according to international standards.

Tensile strength: that is, the hardness of the aluminum strip. The higher the tensile strength of the aluminum strip products, the greater the hardness and the smaller the elongation.

Elongation: It reflects the range of use of flat aluminum strips. Under normal conditions, the aluminium strips has the largest elongation and is suitable for deep drawing products.

Related News

- Aluminium Foil For Transformer Usage

- 3004 Aluminum Strip For Lamp Cap

- Aluminum Strips For Medical Bottle Cap

- Aluminum Strip For Louver

- Dry Transformer Aluminum Strip

- Aluminum Strip for Ductwork

- Aluminium strips for cookie cutters

- Coiled Aluminum Strip

- Aluminium Strip For Electrical Transformer Winding

- Aluminium strip belt for duct