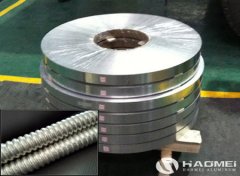

Aluminium strip used for transformer

Haomei is a famous manufacturer of aluminium strip used for transformer, we supply 1050 1060 O aluminum strip 0.2-2.0mm for transformer winding. When applied in dry type transformer winding, the aluminium strip for transformer is known as low cost, besides the copper strip can also be used, what are the difference between aluminium strip and copper strip? Why do more and more people choose to purchase transformer aluminum strip rather than copper strip? Let us have a look!

1. In principle, whether it is a copper or aluminum strip coil transformer, as long as it can meet the national standards, it can safely and reliably meet the requirements of operation.

2. Due to design reasons, aluminum strip coil transformers are thinner and lighter than copper coil transformers.

3. Due to the different material characteristics of aluminum and copper (such as specific gravity, resistivity, conductivity, etc.), the unit prices of the two materials are different. Finally, under the premise of meeting the same standards, the coil material of the aluminum coil is compared with the copper coil. The cost of aluminum strip for transformer is only about 70% of the copper coil, the overall cost is also lower, of course, because the copper price and aluminum price are also changing at any time, the proportion will also change.

4. Seen from the surface, the thermal stability and dynamic stability of the aluminum coil is not better than that of the copper coil. However, the current density that can be taken by aluminum strip is much lower than that of copper strip (under the condition that the load loss and temperature rise of the transformer are guaranteed). So in the end, the dynamic and thermal stability of the aluminum coil is not necessarily worse than that of the copper coil. Of course, this is also under the premise of reasonable design.

5. In oil-immersed transformers, aluminum strip has better oxidation resistance than copper strip. In epoxy resin cast transformers, the expansion coefficient of aluminum (compared to copper) is closer to that of epoxy resin. When the coil expands and contracts, the epoxy resin is not easy to crack.

6. From the point of view of the transformer manufacturing process, the copper coil is more heat and simpler.

7. Judging from small capacity transformer, the aluminium strip used for transformer can fully meet the requirements, and the cost performance is better.

Related News

- Aluminium Foil For Transformer Usage

- 3004 Aluminum Strip For Lamp Cap

- Aluminum Strips For Medical Bottle Cap

- Aluminum Strip For Louver

- Dry Transformer Aluminum Strip

- Aluminum Strip for Ductwork

- Aluminium strips for cookie cutters

- Coiled Aluminum Strip

- Aluminium Strip For Electrical Transformer Winding

- Aluminium strip belt for duct