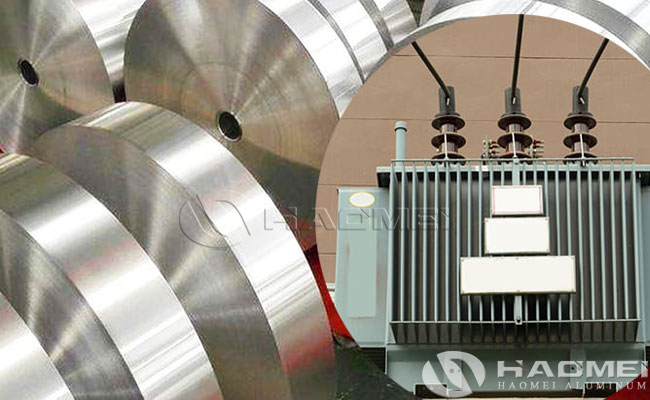

Round Edge Aluminum Strip For Transformer Winding

Round edge aluminum strip for transformer winding is a high-purity aluminum-based conductive material designed for dry-type transformers. Its core advantage is to improve the reliability and safety of windings through special edge processing technology. Rounded edge aluminum strip usually uses 1060-O pure aluminum (aluminum content ≥99.6%), with high conductivity (resistivity ≤0.028Ω・mm²/m) and good flexibility. Its mechanical properties are tensile strength of 110-136MPa and elongation of 3-5%, which can meet the bending and stretching requirements of transformer winding.

Edge processing technology

The rounded edge design uses multiple sets of rolling bearings and end face processing devices to spin the edges of the aluminum strip to form a rounded corner with a radius of 0.1-0.3mm, completely eliminating the burrs and sharp corners of the traditional shear edge. This process not only avoids the risk of scratching the insulation layer, but also reduces the probability of partial discharge and improves the long-term operation stability of the transformer.

Surface quality control

The surface of the aluminum strip for transformer winding must be mirror-grade smooth (Ra≤0.8μm) and free of defects such as scratches and oxidation spots. High-precision cold rolling equipment and online detection systems are used in the production process to ensure that the thickness tolerance is controlled within ±0.005mm and the width tolerance is ±0.1mm.

Quality Standards

Conductivity ≥ 61% IACS

Edge burr height ≤ 0.01mm

Side bending ≤ 3mm/m

Surface insulation resistance ≥ 100MΩ (25℃, 500V test)

Key performance tests

Temperature rise test: Running at rated load for 24 hours, the winding temperature rise must be ≤ 60K (ambient temperature 40℃)

Short circuit withstand test: Withstand 30 times the rated current impact for 10 seconds, no permanent deformation or insulation breakdown

Corrosion resistance test: Salt spray test (5% NaCl solution, 96 Hours) after the surface has no corrosion products.

Material characteristics and core advantages

- High purity and conductivity

Using 1060-O and other grades of aluminum materials, the aluminum content is ≥99.6%, the resistivity is ≤0.028Ω·mm²/m, and the conductivity is second only to copper, but the cost is lower.

Compared with copper strips, the density of aluminum strips is only 1/3 of that of copper, which can reduce the weight of transformers by 30%-50%, and is suitable for weight-sensitive scenes such as aerospace and high-rise buildings.

- Heat dissipation and heat resistance

The thermal conductivity is 237W/(m·K), which is much higher than that of transformer insulation materials. It can quickly transfer the heat of the winding to the radiator, reduce the temperature rise by 10%-15%, and extend the life of the equipment.

Excellent high temperature resistance, can withstand temperatures above 200℃ in a short period of time, and the long-term working temperature is ≤155℃, which can meet the needs of overload operation.

- Machining performance

The edges are designed with rounded corners (R0.5-R2.0mm) to reduce friction and partial discharge between windings, and reduce the risk of insulation breakdown by 40%.

The surface roughness Ra≤0.8μm, no burrs or scratches, ensuring the insulation performance between winding layers.

Round edge aluminum strips for transformer windings have become the core solution for lightweight and efficient transformers through the combination of material science, precision machining and process innovation.

Related News

- High Conductivity Aluminum Strips

- Round Edge Aluminum Strip For Transformer Winding

- 1060 O Aluminum Strip for Cable Shield

- Aluminum Strip For Deep Stamping

- Durable Aluminium Strips For Sun Louver

- Burr-free Round Edge Aluminum Strip For Transformer

- Aluminum Foil Strip For Cable

- 1050 O Aluminium Strip For Transformer Winding

- 0.5mm Aluminium Strip

- Aluminum Strip Standard Size