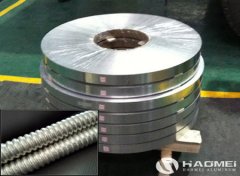

Aluminum Strip For Amour Cable

In power transmission and communication systems, armored cables play an important role with their excellent mechanical protection and electrical performance. The aluminum strip for armour cable, as a key component, not only improves the overall performance of the cable, but also reduces the cost and enhances its market competitiveness.

Aluminum strip for armored cables mostly adopts 1000 series and 5000 series aluminum alloys, such as 1050, 1060, 1070, 5052 and so on. These aluminum alloys have good mechanical properties, corrosion resistance and processability, which can meet the requirements of armored cable on material strength and durability. Especially 5052 aluminum strip is widely used in armored cable because of its high corrosion resistance, high toughness and good welding performance.

The thickness and width of aluminum strip for armored cables need to be customized according to the specifications of the cable and the usage environment. Generally speaking, the thickness of aluminum strip for cable should be not less than 0.15mm to ensure that it provides sufficient mechanical protection. In some high-voltage and large cross-section cables, the thickness of the aluminum strip even needs to reach 0.2mm, while the width of the aluminum strip needs to be precisely controlled according to the design requirements of the cables to ensure that it can tightly wrap the core of the cables and provide uniform protection.

Quality advantages of aluminum strip for armour cable:

- Strong mechanical protection: Aluminum belt armor layer can significantly improve the tensile strength, compressive strength and impact resistance of the cable, effectively preventing the cable from external damage during laying and use.

- Good corrosion resistance: aluminum alloy has good corrosion resistance, can resist the erosion of humidity, acid and alkali and other harsh environments, to extend the service life of the cable.

- Superior electrical performance: the aluminum belt armor layer has high magnetic conductivity, which can reduce the magnetic induction of the metal layer of the cable, reduce the heating of the current and improve the anti-interference performance of the cable.

- Good economy: compared with other materials such as copper belt and steel belt, the price of aluminum belt is cheaper, which can significantly reduce the manufacturing cost of the cable.

Aluminum strip for armored cables is widely used for the following reasons:

- Meet the demand for cable protection: the aluminum strip armor layer can effectively protect the cable core from external damage, to ensure the stable operation of the cable in complex environments.

- Enhance the performance of the cable: by optimizing the alloy state and processing technology of aluminum strip, the mechanical properties, corrosion resistance and electrical properties of the cable can be further improved.

- Reduce cost: the price of aluminum strip is relatively low, the use of aluminum strip as armoring material can significantly reduce the manufacturing cost of cables and improve market competitiveness.

In summary, aluminum strip for armour cable plays an important role in power transmission and communication system with its superior performance and cost advantage. With the progress of science and technology and process improvement, it is believed that the application of aluminum strip in armored cable will be more widely and deeply.

Related News

- Aluminum Strip Standard Size

- Aluminum Strip For Amour Cable

- Copper Foil VS Aluminum Foil For Transformer Winding

- Prepainted Aluminum Strip For Roller Shutter Door

- Hollow Glass Aluminium Strip

- Aluminium Strip For Cable Wrapping

- Anodized Aluminum Strip For Transformer Winding

- Aluminum Strip For Semi-rigid Aluminium Duct

- Aluminium Divider Strip

- Aluminium Strip For Blinds