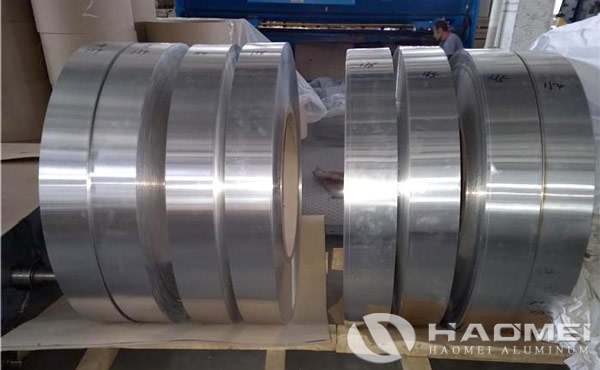

1050 O Aluminium Strip For Transformer Winding

1050 O aluminium strip is a high-purity aluminum alloy material, its aluminum content is usually more than 99.5%, and thus has excellent electrical conductivity, corrosion resistance and good formability. After annealing treatment, 1050 o aluminium strip has a high degree of ductility and flexibility, easy to winding and bending, suitable for complex winding shape. The annealing treatment can reduce the internal stress of the aluminum strip, prevent cracks or deformation in the winding process, and improve the reliability of the transformer winding.

The use of 1050 O aluminium strip for transformer winding has the following features and advantages:

1. High conductivity: 1050 O aluminium strip has close to the conductivity of pure aluminum, conductivity up to 61% IACS (International Annealed Copper Standard), mainly used in the main winding and secondary winding of the transformer, can effectively transmit the current, reduce energy loss.

2. Good ductility and formability: due to the annealed state, 1050 O aluminum strip is very soft, easy to bend and form, suitable for complex winding design.

3. Corrosion resistance: 1050 O aluminum strip has good resistance to atmospheric corrosion and is suitable for a wide range of environmental conditions.

4. Light weight: aluminum density is smaller than copper, the use of aluminum strip can significantly reduce the overall weight of the transformer, easy to transport and installation.

5. Cost-effective: compared with copper materials, aluminum is less expensive, which can effectively reduce the manufacturing cost of transformers.

6. Improvement of efficiency: the use of 1050 aluminum strip for transformer windings can improve the efficiency of the transformer, reduce the heat generated during operation, thereby extending the service life of the transformer.

Manufacturing process of 1050 O aluminium strip for transformer winding:

- Rolling: 1050 aluminum strip is produced through cold or hot rolling process to ensure its uniform thickness and smooth surface.

- Annealing: Annealing treatment is carried out after forming the aluminum strip to obtain O temper characteristics and enhance its flexibility and processability.

- Surface Treatment: The surface of aluminum strip may be oxidized or coated to improve corrosion resistance and insulation.

Applications of 1050 O aluminium strip are:

1. Transformer Windings: 1050 O aluminum strip is widely used in the primary and secondary side windings of transformers, especially in low and medium voltage transformers. The high electrical conductivity and good formability of aluminum strip make it ideal for use as a winding material.

2. Power transmission equipment: in addition to transformer windings, 1050 O aluminium strip is also used to manufacture other power transmission equipment in the conductive parts, such as bus bar, terminal blocks, etc..

3. Electronic equipment: in some electronic equipment, 1050 O aluminum strip can also be used to make heat sinks, conductive connectors and other components.

1050 O aluminium strip for transformer winding has become a commonly used conductive material in transformer windings and other power transmission equipment due to its excellent conductivity, good formability and cost-effectiveness. Proper use and maintenance ensures its efficiency and reliability in a variety of applications.

Related News

- Aluminum Foil Strip For Cable

- 1050 O Aluminium Strip For Transformer Winding

- 0.5mm Aluminium Strip

- Aluminum Strip Standard Size

- Aluminum Strip For Amour Cable

- Copper Foil VS Aluminum Foil For Transformer Winding

- Prepainted Aluminum Strip For Roller Shutter Door

- Hollow Glass Aluminium Strip

- Aluminium Strip For Cable Wrapping

- Anodized Aluminum Strip For Transformer Winding